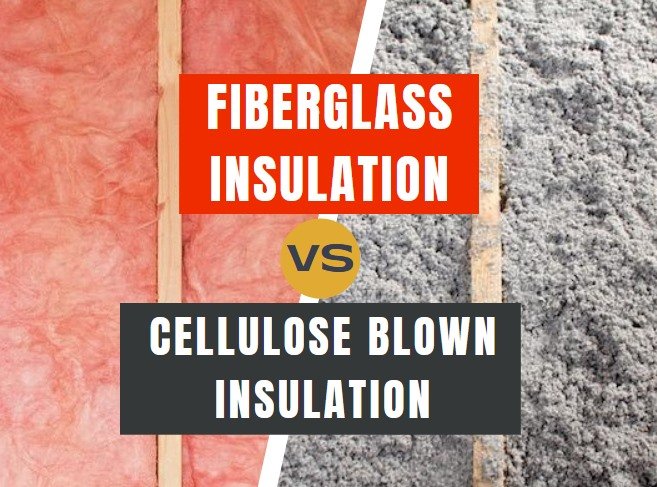

Fiberglass vs cellulose-blown insulation represents two primary types of home insulation materials. Fiberglass, particularly fiberglass batts, is a widely chosen option for attic insulation due to its effectiveness and ease of installation.

Meanwhile, cellulose insulation, often used as loose-fill fiberglass, has been gaining popularity among homeowners seeking energy cost savings and improved thermal performance, especially in post-frame buildings.

Both materials increase your home’s energy efficiency in various ways. We have outlined the distinctions below to help you choose one for your house more wisely.

Fiberglass Vs. Cellulose Blown Insulation

Fiberglass, often used in the form of batt insulation, is manufactured from glass fibers and recycled glass, while cellulose is derived from processed paper fibers. Although neither material is an air barrier, both are effective insulators, with fiberglass providing reliable condensation control and cellulose offering a more eco-friendly option.

Homeowners looking to make healthier and more ecologically sound decisions are increasingly choosing cellulose.

Cellulose Insulation

Cellulose Insulation: Compared to fiberglass insulation, cellulose costs more per square foot. It is primarily offered as blown-in insulation, requiring a blowing machine to blast or pour into an open new wall cavity, an enclosed existing wall, unfinished attic floors, and other hard-to-reach areas.

This makes it a versatile option for comprehensive coverage in areas like attic insulation. But even at extremely cold temperatures or when squeezed, it doesn’t deteriorate, and its R-value doesn’t decrease.

Compression happens when insulation is built incorrectly, has boxes or other heavy objects stacked (think of all the stuff in your attic), is often walked over, has moisture damage, or has compressed against itself through time and space.

Fiberglass Insulation

Fiberglass insulation, including batts and loose-fill fiberglass, is often more budget-friendly but can experience a reduction in R-value in extremely low temperatures or during significant temperature fluctuations.

When installing fiberglass insulation, it’s important to ensure it’s properly fitted to maximize its insulating properties.

Available in both blanket (batt) and loose-fill forms, fiberglass insulation is straightforward to install, allowing for easy placement between studs, joists, and beams.

Despite being a good, economical option, it is not considered ecologically friendly. Although the weight of cellulose insulation vs fiberglass is rot- and mold-resistant, it does lose R-value when squeezed.

- Energy Efficiency

Like spray foam insulation, fiberglass vs cellulose-blown insulation restricts airflow, contributing to energy savings on heating and cooling bills. According to a University of Colorado research, cellulose insulation reduces air leakage by 38%, making it an effective option for areas prone to air leakage, such as attic insulation.

More than 30% of heat or air conditioning can escape because fiberglass insulation cannot stop air from traveling through it.

Read also: Does Fiberglass Insulation Burn?

- R-value

A product’s R-value measures its resistance to heat flow. When the R-value increases, the insulation keeps more heat from escaping. Insulation for homes typically has to have an R-value of 38 or above.

Since cellulose insulation has an R-value of around 3.8 per inch, you would require about 10 inches of thick insulation to achieve R-38. Since fiberglass insulation only has an R-value of about 2.2 per inch, substantially thicker insulation is required to attain the same R-value of 38.

- Cost

Fiberglass and cellulose insulation are inexpensive and cost around the same per inch. However, cellulose insulation is typically more expensive since it requires expert installation and specific knowledge.

- Installation Process

Installing cellulose insulation requires specialized equipment, such as an insulation blower. This process involves blasting or spraying the fibers into targeted areas, ensuring a tightly packed and uniform insulation layer. Given the complexity of cellulose installation, it is typically handled by professionals.

In most cases, fiberglass insulation comes in rolls or batts. Fiberglass insulation must be cut adequately around obstructions like electricity plugs to be effective. It can take a long time to do this. You may put fiberglass without a professional’s help if a person is ready to accept a less effective result.

Disadvantages of Cellulose Insulation

If we talk about fiberglass vs cellulose-blown insulation, you need to change the wiring in your home or make other changes. Cellulose insulation is one of the hardest materials to work with.

When the cellulose cavity is punctured, the substance merely oozes out of the hole. We have previously discussed the consequences of large cavity insulation gaps.

On the other hand, you won’t be able to remove glued-in cellulose from your walls without extensive remodeling work.

Weight of Cellulose Insulation Vs. Fiberglass

How It Works

Cellulose insulation comprises cellulose cells, which naturally act as insulators. Besides shredded paper, it contains a fire-retardant chemical called borate. As the paper disintegrates, it is transformed into fibers that act as insulators.

Numerous small glass threads that make up fiberglass insulation are packed with air bubbles. These air bubbles slow the heat transmission.

Pros and Cons

Insulation made of fiberglass is more prevalent and simpler to install. However, it is potentially explosive and does not stop air loss. In extremely low temperatures, fiberglass insulation rapidly loses heat.

A high R-value, greater energy efficiency, and better sound insulation are two benefits of cellulose insulation.

The Disadvantages of Cellulose Include the Following:

- It is more pricey and requires installation by professionals.

- There may not be any updates to local, regional, or state building codes for cellulose insulation.

- Dust: Blown cellulose produces dust, which can enter a home through minuscule cracks or insufficient sealing around fixtures. A health risk exists here.

- It is expensive to remove cellulose insulation.

- Weight: Fiberglass insulation weighs less than cellulose insulation for the same R-value. Therefore, before selecting the insulating material, you should check the build structures for indications of weakness.

Read also: How to Remove Insulation From Attic

To choose between cellulose and fiberglass, homeowners must consider various factors. While cellulose insulation is made from recycled material, offering an eco-friendly option, fiberglass insulation is known for its ease of installation and cost-effectiveness.

Both materials provide effective solutions when considering loose-fill insulation, but the choice often depends on specific home insulation needs and personal preferences.

The wet spray takes a very long time to dry. However, it is employed for better sealing. You cannot cover or dry a freshly insulated wall with sheetrock until that time. You’ve reached the end of the fiberglass vs cellulose blown insulation article.