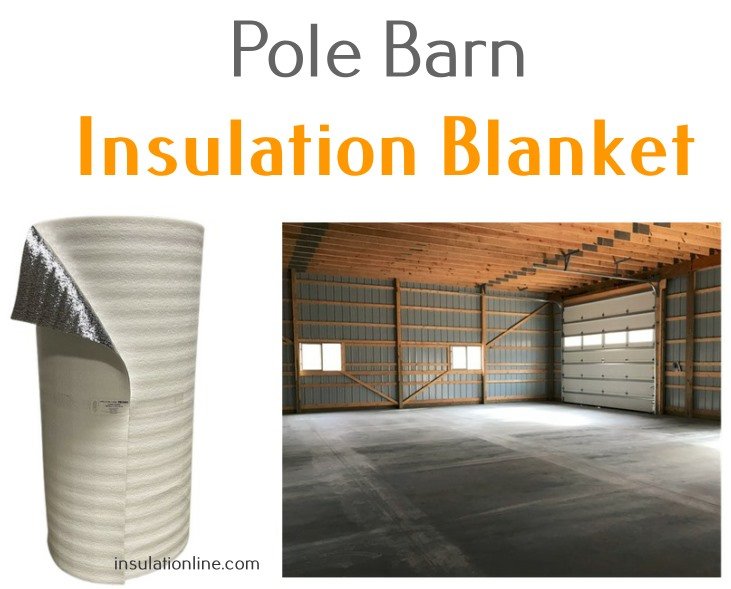

A pole barn insulation blanket is an essential component of post-frame building construction, playing a vital role in condensation control and energy efficiency. Innovative insulation techniques, such as using a vapor barrier, can significantly manage heat input and loss.

This is especially important in pole barns, where controlling air leakage and maintaining indoor temperatures can lead to substantial energy savings.

How to Insulate Your Pole Barn

Acknowledge the Importance of Insulation for You and Your Pole Barn

Insulation, particularly polyethylene foam, will assist in keeping the inside temperature steady in your pole barn structure. This steady temperature is crucial for condensation control and maintaining the structural integrity of the post-frame construction.

Therefore, it will also be helpful in reducing energy bills.

- Reduce the Price of Energy

Heating and cooling a pole barn is an expensive financial commitment. Increasing your insulation’s R-value, which measures how well it can fend against heat flow, may save you much money.

Using high-quality insulation materials, such as polyethylene foam, can enhance the energy efficiency of your pole barn, leading to lower energy bills and improved condensation control. Having high composite R-values for your walls and ceilings is generally better.

- Prevent Degradation and Damage

Rust, mold, and mildew can develop from excessive moisture and condensation resulting from uncontrolled air movement. Proper insulation, especially on the crawl space floor, crawl space ceiling, and crawl space walls, can mitigate these issues.

These problems can potentially harm not just the structure of the building but also the automobiles, machinery, and other items stored within.

- Make the Environment Healthier

By regulating the heat, temperature, and even noise in a pole barn, people and animals may live in a healthier environment overall. Effective insulation, such as polyethylene foam, plays a key role in maintaining indoor air quality and creating a comfortable living or working space within the pole barn.

Be Specific About How You Intend to Use Your Pole Barn

Do you want a pole barn garage for a place where you’ll probably spend a few hours at a time working in nice weather? Will you be able to spend the entire day in your “man cave” (or “woman shed”). Does your attic have insulation? What equipment and materials are you planning to insulate a pole barn?

Read also: How Thick Should Attic Insulation Be

There is no one-size-fits-all approach to insulation in a building. Answering questions like those is essential since your insulation choices should be based on what goes inside your pole barn and what happens inside.

Plan for Insulation from the Design Stage Forward

A correct way to insulate a pole barn might increase its resistance to cold and heat by at least 17%. Your insulation will perform better if there are fewer obstructions in a cavity. Instead of the usual 2 feet with stud wall systems, take columns 8 to 10 feet apart.

Choose Your Insulation Thickness Wisely

The R-value indicates the insulative properties of the material used. One or two-inch insulation can be placed on the exterior of the building. A six-inch fiberglass batt typically has a value of R-19 and is thicker than generally applied directly under steel.

Choose Wisely: Cellulose, Foam, or Fiberglass Insulation?

The three main types of insulation blankets are cellulose, foam, and fiberglass. Attempt to match the material you choose to your demands and financial constraints.

- Fiberglass

This is the accepted practice in the sector. It is portable and frequently the cheap way to insulate a pole barn. Fiberglass insulation may be blown in and comes in rolls, batts, or loose fill forms. Most construction workers and builders can correctly install fiberglass insulation in rolls or batts. However, blown fiberglass requires specialized tools, safety gear, and instruction.

- Foam

Foam often costs more, even though it can insulate a pole barn construction quite well. It will cost money, and you might need to pay someone other than your builder to install it.

- Cellulose

Attic spaces frequently receive this kind of blown insulation. The R-value per inch is slightly greater than blown-in fiberglass and is typically created from renewable resources.

Pole Barn Insulation Blankets

Rolled fiberglass batts are the tried-and-true standard of pole barn insulation kits; although they are notoriously scratchy, they are inexpensive, readily accessible, and simple to install.

Although this form of insulation is perhaps the most often used, many more possibilities are available, each with unique characteristics that may help you choose the type of insulation that best meets your needs.

Although it tends to retain moisture, rock wool insulation is more thermally efficient than fiberglass and is frequently employed for its ability to withstand fire.

However, more costly and often difficult to get, cotton/denim (or “blue jeans”) insulation may have a very high R-value and is superior at reducing noise. Having stated that floors and ceilings are not frequently covered with it.

Wrapping Up

Effective insulation of your pole barn is crucial for some reasons, including financial savings, equipment protection, and safety for you and your family. Decide how you’ll use your pole barn before you build it, whether you decide to build it yourself or hire a constructor.

Formaldehyde-free fiberglass insulation is a popular choice among the various options due to its effectiveness and safety. It’s essential to consider the specific needs of your pole-building insulation to ensure optimal performance and durability.

Then, familiarize yourself with your alternatives. Making wise choices will allow you to create a well-insulated pole barn insulation blanket that is intended to last for many years.